| |

| Twin Sash Balance |

Twin Sash Balance

Adjustable |

Overhead

Mortise Tape Balance |

Side Mount

Mortise

Tape Balance |

|

|

|

|

|

|

|

|

| Acme Twin Sash Balance |

Acme Adjustable Sash Balance |

Overhead Mortise Tape Balance |

Side Mount Tape Balance |

|

|

|

|

|

| Sold by the Each |

Sold by the Each |

Sold by the Pair |

Sold by the Pair |

4½ Acme Twin 4½ LB. per cable

1 per box

Double installation

Sash Weight of 8 to 9 LB. per cable

6 Acme Twin 6 LB. per cable

1 per box

Double installation

Sash Weight of 10 to 12 LB. per cable

8 Acme Twin 8 LB. per cable

1 per box

Double installation

Sash Weight of 13 to 16 LB. per cable

10 Acme Twin 10 LB. per cable

1 per box

Double installation

Sash Weight of 17 to 20 LB. per cable

12 Acme Twin 12 LB. per cable

1 per box

Double installation

Sash Weight of 21 to 24 LB. per cable

14 Acme Twin 14 LB. per cable

1 per box

Double installation

Sash Weight of 24 to 28 LB. per cable

16 Acme Twin 16 LB. per cable

1 per box

Double installation

Sash Weight of 29 to 32 LB. per cable |

#1 Duplex Adj 4 to 8 LB. per cable

1 per Box

Double installation

Sash Weight of 8-16 LB

#2 Duplex Adj 8 to 12 LB. per cable

1 per box

Double installation

Sash Weight of 16 to 24 LB.

#4 Duplex Adj 12 to 18 LB. per cable

1 per box

Double installation

Sash Weight of 24 to 36 LB. per cable

#5 Duplex Adj 18 to 24 LB. per cable

1 per box

Double installation

Sash Weight of 36 to 48 LB. per cable |

4½ Overhead Mortise 4½ LB. per Balance

2 per box

Double installation

Sash Weight of 8 to 9 LB. per cable

6 Overhead Mortise 6 LB. per Balance

2 per box

Double installation

Sash Weight of 10 to 12 LB. per cable

8 Overhead Mortise 8 LB. per Balance.

2 per box

Double installation

Sash Weight of 13 to 16 LB. per cable

10 Overhead Mortise 10 LB. per Balance

2 per box

Double installation

Sash Weight of 17 to 20 LB. per cable

12 Overhead Mortise 12 LB. per Balance

2 per box

Double installation

Sash Weight of 21 to 24 LB. per cable

14 Overhead Mortise 14 LB. per Balance

2 per box

Double installation

Sash Weight of 24 to 28 LB. per cable

16 Overhead Mortise 16 LB. per Balance

2 per box

Double installation

Sash Weight of 29 to 32 LB. per cable |

4½ Side Mortise 4½ LB. per Balance

2 per box

Double installation

Sash Weight of 8 to 9 LB. per cable

6 Side Mortise 6 LB. per Balance

2 per box

Double installation

Sash Weight of 10 to 12 LB. per cable

8 Side Mortise 8 LB. per Balance

2 per box

Double installation

Sash Weight of 13 to 16 LB. per cable

10 Side Mortise 10 LB. per Balance

2 per box

Double installation

Sash Weight of 17 to 20 LB. per cable

12 Side Mortise 12 LB. per Balance

2 per box

Double installation

Sash Weight of 21 to 24 LB. per cable

14 Side Mortise 14 LB. per Balance

2 per box

Double installation

Sash Weight of 24 to 28 LB. per cable

16 Side Mortise 16 LB. per Balance

2 per box

Double installation

Sash Weight of 29 to 32 LB. per cab |

| more information |

more information |

more information |

more information |

| |

|

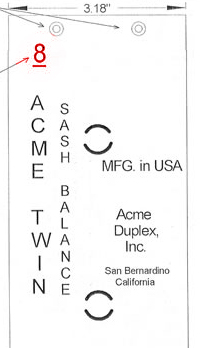

Size of twin balance

is stamped into the case

Often you will need a wire brush

to see the number |

|

Stamp number on older boxes

is higher in the corner

|

|

Replacing Original Window Balances

Today, people appreciate the craftsmanship and quality of original wood sash windows. Gone are the days of simply ripping out beautiful old wood windows and replacing them with aluminum or plastic windows. In fact, many communities require maintenance or replacement of original windows in older neighborhoods, in order to maintain the ambience of the streetscape.

Wood has always been a superior insulator against changing outside temperatures, but glass is not. Therefore, many are refitting old windows with new sashes or double-pane glass to decrease the heat loss in winter, and keep the heat out during the summer. Sunscreen for glass is also available today.

One alteration that is often overlooked when windows are refitted is the process of adjusting the weights to “carry” the increased weight of the new sash glass. Undersizing the balance can cause injury, if the sash falls onto an unsuspecting hand.

For hundreds of years (up to the 1960’s) sash window balances were popular, because without air conditioning, opening the top and the bottom sashes provided a convection air-flow that brought cooler air in through the bottom, while allowing warmer air to escape at the top. Today, with high-energy costs, this principle still works in areas where the evening air cools, compared to the daily high temperatures. This practical application, along with the resurgence of home designs that duplicate our older classic homes, has been responsible for the resurgence in popularity of the double-hung window. |

Repairing Lead Window Weights

Prior to the 1920’s, homes generally used pulley and weight systems to balance the window sash. The weight was typically lead or brick, and was slightly heavier than the sash. Old cotton ropes, with plenty of use, might need to be replaced every twenty years or so. The cotton rope was attached to the weight behind the window frame molding, and was fed up through a pulley in the frame, then back down to the window.

To repair the ropes, some windows have a slot to get access to the weight. If no access slot was provided, the interior (or exterior in some cases) window molding must be removed to gain access to the weight.

Using a sharp knife or razor, cut the paint along the seams of the molding to prevent further paint damage. Carefully remove the molding on both sides. Access the space in the wall where the weight is and retrieve it.

Cut the old rope from the weight and window sash and remove it, taking care to notice how the weight was attached to the rope. Note: Some knots should be duplicated, and some have another pulley on the weight with the rope attachment in another place.

Replace the rope with a very similar thickness of rope (using a different weight of rope can cause the rope to jump the pulley). However, rope with nylon blend may not need to be replaced as often, so shop for rope that looks the same, as the old rope but has more strength due to new material development.

Replace the moldings, fill cracks and paint. You will probably not need to do this again in your lifetime. |

Replace with an ACME® side mortise sash balance (also called a tape balance)

If you do not like this approach, another solution was developed to replace the pulley. This is called the mortise or tape balance. Mortise retractable spring balances use a strip of metal that is wound tightly into a contained unit. ACME® side mortise balances many times fit in the same hole left by the rope pulley in the window frame. The weight is no longer needed, so can be left in the wall, meaning you don’t have to remove and paint the window casing or trim. *

First, remove the sash and weigh it. Select the proper ACME® mortise weight size, and add a few pounds for safety (see sizing charts). Each side carries half of the weight, so divide the weight by two to get the weight for each balance. Remove the pulley from the mortised slot in the window frame. Compare the ACME® mortise with the slot, remove any additional material with a hammer and chisel or drill and bit. See video for an example.

When the ACME® mortise balances are securely fit and screwed to the frame, pull the tape out of one side and attach the tape to the window with the included hook. Take extreme care not to “snap” or let go of the tape as it may damage the internal spring. Do the same with the other side. Set the sash in the window and replace stop molding and touch-up paint.

The ACME® double-hung window spring mortise balance will provide many decades of service, and preserve the look and feel of your historic windows.

* Note: some choose to insulate this area when it has been vacated; however, this require removing internal or external window casing or trim.

|

| |

| |

| |

| |